Waste Within the Clothing Value Chain

I recently began a graduate certificate program in Corporate Sustainability and Innovation. For a class on the circular economy, I wrote this paper, and am posting it here because I thought the information to be worth sharing.

Clothing is a constant and essential part of the human experience, serving utilitarian functions of warmth, protection, and comfort, as well as cultural and emotional functions through fashion, personal expression, and style. Globally, clothing is currently a 1.3 trillion-dollar industry, employing more than 300 million people along the value chain (Ellen MacArthur Foundation, 2017). At the beginning of the twentieth century, apparel represented 14% of family expenditures for United States households (Thompson, 2012). Now, though, it represents only 3.1 percent of expenses (U.S. Department of Labor, 2017). On the surface, the current low percentage share of expenses may make the apparel industry seem an insignificant priority for examination—that (positively) the industry has figured out how to ease the burden on household budgets. This decline may even give the illusion that demand for the clothing industry is at risk altogether (Rupp, Whiteaker, Townsend, & Bhasin, 2018). The truth, however, is quite a bit more complex. The “fast fashion” phenomenon is the cause of the decrease in household clothing expenses, but that decrease actually simultaneously represents a dramatic increase in consumption—on average 64 garments per person per year (Cline, 2012), which is an astonishing 400% increase over the course of just two decades’ time (Ross & Morgan, 2015). Furthermore, the Ellen MacArthur Foundation projects that demand for clothing will continue to increase, driven primarily by emerging markets in Asia and Africa, to reach 160 million tons (more than three times the current amount) in 2050 (p. 21).

This level of consumption—and the industrial model of production that enables consumers to purchase apparel so inexpensively—is simply unsustainable. The clothing system, much like so many other industrial systems in our current global economy, is incredibly wasteful. As Stuchtey, Enkvist, and Zumwinkel (2016) observe, “a combination of historic reasons and inadequate public governance has led to a situation where … the systems are stuck in an inefficient structure. The results are huge economic and environmental losses” (p. 109).

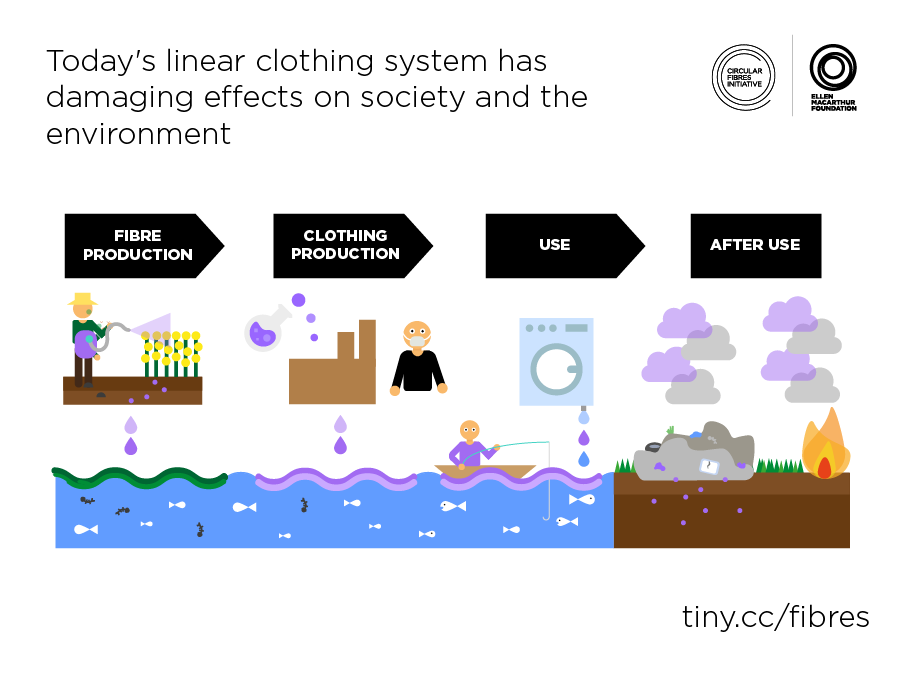

Waste from the clothing system’s material flows can be considered through four phases: (1) the fiber and textile production industry, (2) the fashion and clothing production industry, (3) use and re-use, and (4) after use.

Source: Ellen MacArthur Foundation (2017)

Source: Ellen MacArthur Foundation (2017)

The fiber and textile production industry includes both natural and manufactured plastic-based fibers. Activities in this phase span from raw materials production (farming, oil extraction, and processing), to yarn production, to fabric production, to fabric finishing activities (including dyeing, bleaching, and coating). Clothing industry activities include garment design, garment manufacturing or tailoring, distribution and retailing, and other activities like fashion shows (Gardetti & Torres, 2013). Clothing use and re-use activities include wearing, storing, laundering, mending, and reselling the garment by any of its owners throughout its cycle of use. Post-use activities include disposal such as by recycling, landfill, or incineration.

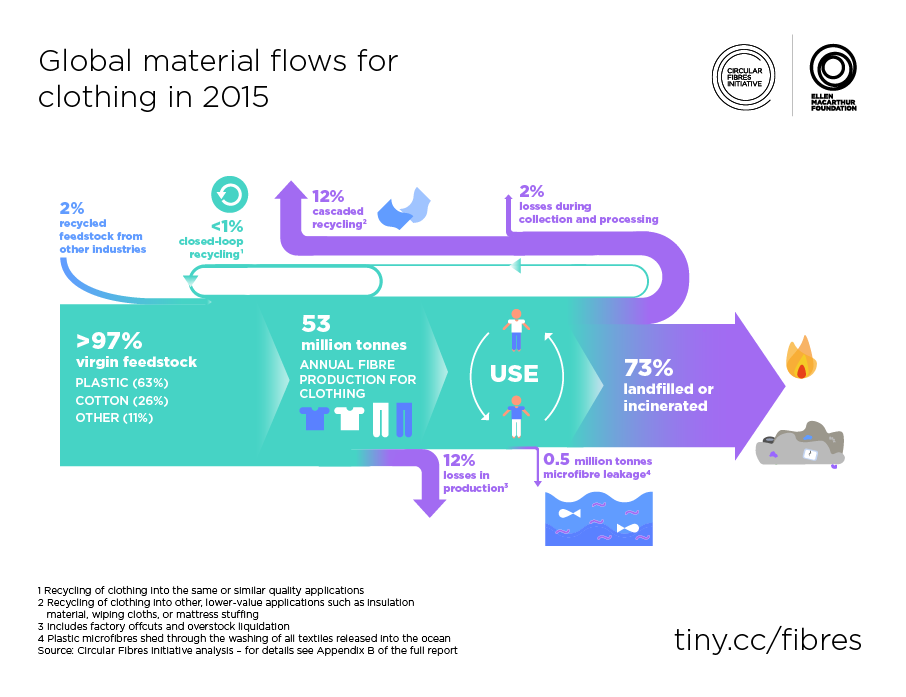

The below infographic diagram by the Ellen MacArthur Foundation outlines the material waste created in each phase of the clothing system’s value chain. The sections following describe these and other forms of waste found in each of the phases along the clothing value chain.

Source: Ellen MacArthur Foundation (2017)

Source: Ellen MacArthur Foundation (2017)

Waste in Fiber and Textile Production

In the 2015 documentary The True Cost, the filmmakers reveal how the chemical fertilizers and pesticides intended to improve yields in cotton fields are what are becoming known as “ecological narcotics—the more you use them, the more you need to use them”. This increasing non-renewable resource use and soil contamination and degradation isn’t just an environmental issue, though—despite the original intention of reducing the end consumer’s cost of clothing and increasing availability of clothing, the use of these chemicals is actually chipping away at the clothing system’s fundamental utilitarian purpose of protecting people. In the region of Punjab, India, for example, the pesticides designed by Monsanto for their proprietary cotton seeds have been shown to dramatically increase the number of birth defects, cancers, and mental illness. Additionally, far too many cotton farmers feel so trapped in their terrible economic situations (brought on by increasing expenses and crop yields that aren’t increasing as promised) that they actually drink those pesticides. “In the last 16 years, there have been more than 250,000 recorded farmer suicides in India… it’s the largest recorded wave of suicides in history” (Ross & Morgan, 2015). The astoundingly low quality of human life—and even loss of life altogether—of the laborers and communities connected directly and indirectly to the fiber production part of the system is a devastating cost hidden to the vast majority of apparel consumers.

Once the fibers reach the factories for production into finished fabrics, dye and other chemical waste associated with fabric coating and other special treatments is released into the water streams, devastating local ecosystems. These harmful chemicals likely exist even in finished garments as well; although not well-assessed, chemical waste during the garment use phase continues to impact ecosystems through laundering and perhaps even our own bodies by wearing treated garments (Ellen MacArthur Foundation, 2017).

Waste in Clothing Production and Distribution

From a materials perspective, garment manufacturing processes currently create 12% material waste in factory offcuts and overstock liquidation (Ellen MacArthur Foundation, 2017). But material waste is hardly the only waste created in this phase—fast fashion’s pressure on the speed and cost of manufacturing have caused a number of human capital losses. Sweatshops violate the human rights of factory workers, creating not only an opportunity cost associated with lack of opportunities for these workers’ education and healthcare, but also sometimes even causing deaths—more than 1000 lives were lost in the tragic 2013 collapse of the Rana Plaza factory in Bangladesh (Ross & Morgan, 2015). Additional human capital loss associated with the rise of fast fashion is the rapid decline of the apparel manufacturing industry in America—nearly 650,000 apparel jobs were lost over a ten-year period ending in 2007 (Cline, 2012)—and the global decline of the tailoring and garment repair trades. Demand for these skill sets have all but disappeared (Ross & Morgan, 2015).

When garments are finished, they are packaged for shipment to distribution centers and on to retailers or direct to consumers. In some cases, packaging is intentionally excessively designed for the purpose of elaborate “unboxing” consumer experiences. A certain amount of packaging has a clear purpose that prevents waste from being created, in transit, in the form of damaged goods, but packaging’s purpose is fulfilled once its contents reach their destination, where it then becomes waste. Patagonia, a retailer leading the clothing industry in sustainability initiatives, conducted a series of tests investigating ways they could reduce the plastic waste generated from their product packaging. They tried a number of alternative packaging approaches and found that “[plastic] polybags are critical to insuring that garments stay clean from the finished goods factory through the [distribution center] …. A damaged product that is unwearable has a far greater environmental cost than manufacturing a polybag” (Cohen, 2014). Through these tests, Patagonia was able to identify a number of ways to reduce and mediate the negative impact of their packaging waste.

Waste in Clothing Use

Apparel waste at the consumer level can be assessed both in terms of the technical care of garments, and in terms of social factors associated with the sheer quantity of garment consumption. Since caring for garments is a repeating process, the effects of inefficient water usage and energy systems when washing, drying, and ironing compound over time and can constitute a greater amount of waste than there is in the initial garment production process (Gardetti & Tores, 2013). Laundering produces half a million tons of microfiber leakage into the water streams over the course of one year (Ellen MacArthur Foundation, 2017). Additional hazardous waste is also created through the variety of chemicals used in dry cleaning processes (Jung & Jin, 2014).

With the significantly decreased cost of clothing, it’s easier than ever to buy more of it. Americans each on average purchase a little more than one new piece of clothing every week (Cline, 2012). The reality persists, however, that we only wear one day’s worth of clothing each day, so our increasing clothing collections are wasting more and more physical space, which has financial implications. Despite the fact that American closet sizes have increased by 60 percent since the 1960s, most people still don’t have room for all their clothes, and it’s not at all unusual for people to complain of having nothing to wear. (Weber, 2015). People have the wrong clothing items, and they have too many of them—leading to a waste in psychological energy through anxiety. Still more mental health risks come from the social pressures of blind fast fashion consumerism that lead people to compare their ongoing accumulation of the latest fashions with that of others, and the perception that this cycle should be a central part of their identity formation (Gardetti & Torres, 2013).

Minimalism-driven self-help resources have stepped in to address this anxiety with tips on purging our closets, to counter the “haul” mentality so prevalent in this era of fast fashion. Advice such as, “Keeping it in your closet … will only [make] you feel guilty every time you see it.… Let the item go. Use it as a lesson for how to make better choices when shopping in the future” (Simple Lionheart Life, 2017), leads us to the waste in the final phase of the clothing system.

Waste After Clothing Use

When garments no longer serve our interests, we make decisions about what to do with them—to mend them, up- or down-cycle them, sell them, trade them, give them away, donate them, or simply discard them into the trash. Fast fashion has created a situation where we only keep about 21 percent of the clothing we buy every year (De Jesus & Soriano, 2012). Globally, the average number of times a garment is worn before it is no longer used (clothing utilization) has decreased by 36 percent over the last 15 years. The actual utilization in high-income countries like the United States, though, is a quarter of the global average—much less than in low income countries (Ellen MacArthur Foundation, 2017). Fifteen percent of the textiles Americans don’t keep every year is donated or recycled, but surprisingly and unfortunately, the remaining 85 percent (an astounding 21 billion pounds or 70 pounds per person) ends up in the trash for landfills or incineration (Council for Textile Recycling, n.d.). This scale of textile disposal results in the loss of almost all of the material value (less than one percent is recycled into new clothing) as well as being an enormous financial waste of USD 460 billion each year (Ellen MacArthur Foundation, 2017). Savers, a secondhand chain store, conducted a study that showed that 62 percent of the people who admitted to throwing clothes in the trash did so because they thought their stuff wasn’t good enough to donate (p. 8). Correcting this false consumer perception would not completely solve the problem, however, as even the act of donation creates its own form of waste. Due to the sheer scale of current consumption levels, only between ten and twenty percent of donations can realistically be sold by the organizations that receive them. The remaining clothing is sold to wholesalers who distribute them in bulk to markets abroad such as in African countries where, although demand for low-priced clothing exists in these areas, this practice actually steals textile jobs and destroys local clothing industries. The secondhand clothing market, in this case, actually profits from the poor rather than benefitting them.

Conclusion

Clothing companies and their consumers are becoming increasingly aware of the broad range and severity of environmental and sustainability issues that exist along the clothing value chain. However, companies are so far only focusing their sustainability initiatives on the use of more environmentally friendly materials (such as for eco-fashion) and optimizing processes to reduce waste through lean manufacturing. Since clothing companies are still operating under an economic model that prioritizes growth in consumption, though, the main problems in clothing waste are not being addressed (Jung & Jin, 2014). Until garment consumption levels are drastically reduced and garment durability and utilization is increased, the system as a whole will remain unsustainable.

References

- Cline, E. (2012). Overdressed: The Shockingly High Cost of Cheap Fashion. Penguin Group.

- Cohen, N. (2014, July 11). Patagonia’s Plastic Packaging – A study on the challenges of garment delivery [Web log post]. Retrieved from https://www.patagonia.com/blog/2014/07/patagonias-plastic-packaging-a-study-on-the-challenges-of-garment-delivery

- Council for Textile Recycling. (n.d.). The Facts About Textile Waste [Infographic]. Retrieved February 14, 2018 from http://www.weardonaterecycle.org/about/issue.html

- De Jesus, J. & Soriano, T. (2012, March 9). Ethical Style: Where Do My Used Clothes Go? Good Magazine. Retrieved February 14, 2018 from https://www.good.is/articles/ethical-style-where-do-my-used-clothes-go

- Ellen MacArthur Foundation (2017, November 28). A new textiles economy: Redesigning fashion’s future [Report]. Retrieved from http://www.ellenmacarthurfoundation.org/publications

- Gardetti, M.A. & Torres, A.L. (2013). Sustainability in Fashion and Textiles: Values, Design, Production and Consumption. Retrieved from http://books.google.com/books

- Jung, S., Jin, B. (2014). A theoretical investigation of slow fashion: sustainable future of the apparel industry. International Journal of Consumer Studies, 38(5), 510–519.

- Ross, M. (Producer) & Morgan, A. (Director). (2015). The True Cost [Video file]. Retrieved from https://www.netflix.com

- Rupp, L., Whiteaker, C., Townsend, M., Bhasin, K. (2018, February 5). The Death of Clothing. Bloomberg. Retrieved February 13, 2018, from https://www.bloomberg.com/graphics/2018-death-of-clothing

- Simple Lionheart Life. (2017, March 9). 12 Reasons We Keep Clothes We Don’t Wear and How to Move Past Them [Web log post]. Retrieved February 13, 2018, from http://simplelionheartlife.com/reasons-keep-clothes-we-dont-wear/

- Stuchtey, M., Enkvist, P.-A., & Zumwinkel, K. (2016). A Good Disruption: Redefining Growth in the Twenty-First Century (1st edition). Bloomsbury Business.

- Thompson, D. (2012, April 5). How America Spends Money: 100 Years in the Life of the Family Budget. The Atlantic. Retrieved February 14, 2018, from https://www.theatlantic.com/business/archive/2012/04/how-america-spends-money-100-years-in-the-life-of-the-family-budget/255475

- U.S. Department of Labor, Bureau of Labor Statistics. (2017). CONSUMER EXPENDITURES—2016. Retrieved from https://www.bls.gov/news.release/cesan.nr0.htm

- Weber, S. (2015). How Consumers Manage Textile Waste. (Master’s Thesis, University of Waterloo). Available from UWSpace.

Stay In Touch!

Get occasional letters from Michael & Hannah.