Increasing Circularity Within the Clothing System

I recently began a graduate certificate program in Corporate Sustainability and Innovation. For a class on the circular economy, I wrote this paper, and am posting it here because I thought the information to be worth sharing.

The fashion industry is the world’s second largest polluter, right behind the oil industry (Sweeny, 2015). As the industry and its consumers have become aware of the scale of these problems in recent years, efforts are being made to address waste across the clothing system. Although material flows in the clothing system are evaluated in four phases—(1) fiber and textile production, (2) fashion and clothing production, (3) use and re-use, and (4) after use—the distinctions between the phases tend to blur in an analysis of increasing circularity.

Fiber and Textile Production

Companies are primarily working to eliminate waste in the first phase of the clothing system by replacing harmful chemicals with environmentally friendly, renewable raw materials (Henninger, Alevizou, & Oates, 2016). For example, organic cotton is rising in popularity since the enormous quantities of chemical fertilizers and pesticides for conventionally produced cotton are destroying crop yields and soil quality. Although organic still only accounts for about one percent of all cotton grown, Patagonia has set out to lead the industry, having itself made the switch entirely (Patagonia, n.d.). Additionally, since cotton is the thirstiest crop (water usage is astronomical for both types of cotton), Levi’s has developed production techniques that “can reduce up to 96% of the water normally used in denim finishing” such as by reusing water and developing new finishes that require less water than would traditional processes (Levi’s, 2018).

Industry collaboration has also begun to address harmful chemical waste with a greater impact than any individual company could have on its own. The Sustainable Apparel Coalition (SAC) represents about 40% of the global textile market and issued a restricted substances list. The SAC has also been working on the Higg Index, which is a set of tools that act like a report card, allowing companies to measure and track their operations, so that areas for improvement become clear. Additionally, the activist group Natural Resource Defense Council (NRDC) has developed Clean by Design, a program that advocates that textile mills follow best practices to cut water, energy, and chemical usages. (Bomgardner, 2016).

Clothing Production and Distribution

Eliminating waste in the production of clothing currently focuses primarily on keeping offcuts to a minimum, but there are increasingly circular practices emerging throughout the industry. Traditionally, garments are created through a subtractive process, starting with a piece of material and cutting it down into pieces that are sewn together. Additive processes, however, virtually eliminate offcuts by only using the materials needed. Nike’s Flyknit shoe uppers are one example of an effective, efficient, additive manufacturing process. Nike has engineered a technology that uses strong, lightweight strands of yarn knit differently in different areas, depending on the area’s need for tightness or flexibility, to create a shoe with very little textile waste, and without any reduction in material performance or aesthetic appeal. (Nike, n.d.)

Levi’s has partnered with Evrnu, a startup textile recycler, on a major sustainable apparel innovation advancement to create the first pair of jeans made from recycled post-consumer cotton from old t-shirts (Mantor, 2016), keeping textiles out of the landfill and reducing the need for virgin fibers. Other approaches to increasing circularity in the production phase include designing for durability so that garments last longer (Henninger, Alevizou, & Oates, 2016), upcycling old materials into new garments to extend the life of materials, and designing for recyclability. Recyclability in this case means garments are made of biodegradable material, and if there are accessories, they’re detachable (Weber, 2015). C&A has developed the first cradle-to-cradle certified line of t-shirts, which are fully compostable (FashionUnited, 2017).

When garments are finished, they are packaged for shipment to distribution centers and on to retailers or direct to consumers in plastic polybags and cardboard boxes. Once its contents reach their destination, the packaging becomes waste. Patagonia conducted a series of tests investigating ways they could reduce the plastic waste generated from their product packaging. They tried a number of alternative packaging approaches and found that “[plastic] polybags are critical to insuring that garments stay clean from the finished goods factory through the [distribution center] …. A damaged product that is unwearable has a far greater environmental cost than manufacturing a polybag”. But through these tests, Patagonia was able to identify a number of ways to reduce and mediate the negative impact of their packaging waste, such as using smaller sized polybags when possible, increasing polybag recycling at dealers and distribution centers, and using recycled polybags (Cohen, 2014).

Clothing Use and Reuse

Reducing waste in the end-consumer use phase is being addressed in a wide variety of ways including cultural shifts, new business models, and the resurgence of age-old garment repair. Environmentally friendly laundering technology is also increasingly available both through high-efficiency washing machines that reduce water usage, as well as eco dry cleaning services that eliminate toxic chemicals. Culturally, as people have become more conscious of the damage the fashion industry creates, they’re beginning to use this knowledge in their decisions about what to support when they spend their money. “Trends are no longer the all-powerful dictum they once were…. Consumers now have access to an unprecedented wealth of style information and are beginning to trust their own interpretation and personal taste” (BSR, 2012). Furthermore, “slow fashion” is a socially conscious sustainability movement in contrast with “fast fashion” that aims to shift consumers’ mindsets from quantity to systemic quality—consumers buy high‐quality items less often, and garment workers are paid a living wage with safe working conditions. (Jung & Jin, 2014; Cataldi, Dickson, & Grover, 2017).

In a world well-accustomed to clothing ownership, new business models are being marketed as making it easy to be fashion-forward without having to own and store all the pieces. Clothing rental for rarely-needed things like tuxedos has existed for a while, but in recent years, every-day and maternity clothing rental companies are emerging—Rent the Runway, LeTote, and Gwynnie Bee are a few. A denim leasing business model is even being pioneered by Mud Jeans where “users” pay monthly to lease jeans (repairs included). After a year, the options are to (1) swap their jeans for a new pair and lease for another year, (2) keep the jeans, or (3) return the jeans for a voucher toward their next purchase. (Ellen MacArthur Foundation, n.d.)

Yard sales and donation have long been options for keeping garments in use after the owner is finished. Recently, online businesses have emerged for buying and selling (and in some cases, swapping) high-quality secondhand clothing without the fuss and smells. Each offer their own unique kind of community, removing even more of the hassle of in-person thrift shopping. ThredUp is the largest online thrift and consignment store. Others include Swap, Poshmark, The Real Real, Grailed (exclusively men’s), and Vinted. Facebook also offers a marketplace feature. Patagonia has made garment repair trendy again with their Worn Wear product line, creating a culture of valuing the relationship people have with their clothes and the stories they tell, in order to keep garments in use longer. Levi’s has an Authorized Vintage collection and has also partnered with RE/DONE, a company that remasters vintage Levi’s to bring individuality to luxury fashion. Wearing vintage jeans saves an estimated 65% of the water typically used during the lifecycle of a pair of jeans, since no new water is necessary to grow cotton (Levi’s, 2018).

After Clothing Use

Although textile recycling services aren’t widely known, they do exist and are maturing. Collection bins can be set up in neighborhoods by organizations such as the American Textile Recycling Service, who transport donations to a facility where they’re sorted by what can be resold in a secondhand store, sold to developing markets, used for disaster relief, cut into rags, or shredded into fiber for things like carpet, insulation, and filtration products. This keeps materials in play longer and represent a 15 percent diversion of textile waste from landfills. Emerging textile recycler Evrnu has invented a regenerative fiber made from post-consumer cotton textile waste using 98% less water than it takes to process virgin cotton (Mantor, 2016). Reverso, a collaboration between three Italian textile mills, and Kering, a luxury material developer, have begun to re-manufacture wool off-cuts from garment manufacturing back into high quality yarn for an almost-zero-waste cycle of production for brands (Moorhouse & Moorhouse, 2017). Many retailers have begun to partner with garment take-back programs to start taking responsibility for products’ end of life. I:CO is a global program with partners in more than 60 countries that cascade garments through applications from reuse to recycling. Give Back Box partners with major U.S. retailers including NewEgg, Overstock, Amazon, Loft, and REI to allow people to reuse their online shopping boxes to send old garments to a charity, postage-paid. This reduces cardboard waste and creates a convenient new channel for collection. Blue Jeans Go Green partners with J. Crew and Madewell to collect denim for housing insulation. H&M has established their own take-back program, with an ultimate goal of transforming the fiber so it can be rewoven and remade into new clothes, but since cost-effective recycling hasn’t been found yet, most garments are sent to secondhand stores or are down-cycled into rags or insulation (Szokan, 2016). Brands who want to use recycled fiber are for now confined to using it in limited quantities or small-edition, eco-friendly lines (Bomgardner, 2016).

France became the first country to implement an extended producer responsibility (EPR) policy for end-of-use clothing in 2007. This means clothing brands are responsible for the cost of collection, treating and recycling their end-of life products. The policy has created consumer awareness, contributed to a 300 percent increase in collection and recycling rates of post-consumer textiles since 2006, and supports collaborative research and development for both fashion producers’ and recyclers’ issues (Bukhari, Carrasco-Gallego, & Ponce-Cueto, 2018).

Is it Circular Though?

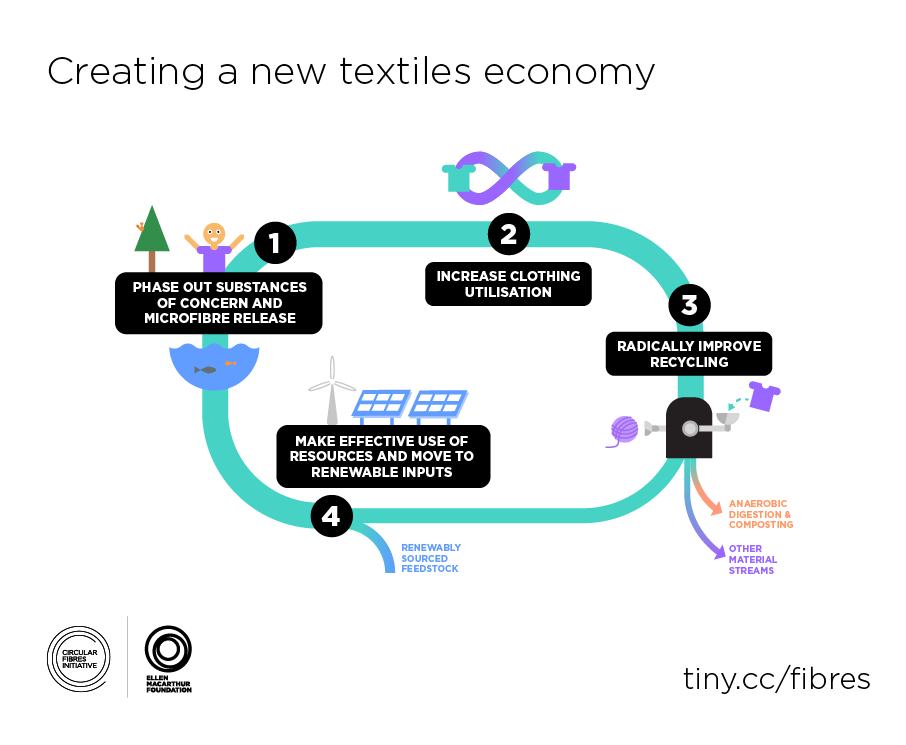

Collectively, the above solutions represent individual stakeholder attempts to make the industry more sustainable. While the majority of efforts are focused on reducing the negative impact of the current linear system, a circular, restorative vision for the industry has been painted by the Ellen MacArthur Foundation.

Source: Ellen MacArthur Foundation (2017)

Source: Ellen MacArthur Foundation (2017)

True circularity, as defined by the foundation, “is restorative and regenerative by design, and aims to keep products, components and materials at their highest utility and value at all times, distinguishing between technical and biological cycles.” In their recent report, the foundation describes the changes that need made to not only end the damage created by the industry, but also to create accretive benefits for business, society, and the environment. “In such a new textiles economy, clothes would be designed to last longer, be worn more, and be easily rented, resold or recycled, and no toxic substances or pollutants would be released during their production and use” (Ellen MacArthur Foundation, 2017).

But this vision remains a vision, for now. Demand for clothing is still growing quickly, driven by emerging markets in Asia and South America. With population growth and a rise in standards of living, total clothing sales could reach 175 million tons in 2050—more than three times today’s sales (Ellen MacArthur Foundation, 2017). If the vision for a circular economy in the fashion industry is to manifest, an unprecedented scale and depth of collaboration will be required. A simple eco-friendly material change isn’t sufficient; we need to shift our mentality towards understanding all facets of the system (Moorhouse & Moorhouse, 2017). For example, in the fiber and textile production phase, the most significant and circular means of waste reduction will occur when end-of life materials are recycled to regenerate fiber and textiles of an adequate quality for use in new garments. Today, only one percent of textiles are recycled. Closing the materials loop with the final, after-use phase of the clothing system, keeping materials at a high value, and significantly reducing the industry’s reliance on resource-heavy virgin material inputs. This smart, circular regeneration is happening at a small scale with Mud Jeans, Evrnu, and Kering, but until the big, affordable brands find a way to achieve circularity at scale, though, the textile economy will remain unsustainable. Levi’s is taking the vision’s collaboration mandate to heart though—they are sharing their Water<Less™ water reduction methods to inspire industry-wide progress, recognizing that sustainability is a reason for collaboration, and that competition should exist in other areas of the business (Levi’s, 2018).

In the fashion and clothing production phase, designing for recyclability and using recycled materials are circular ideas in theory. However, examples like C&A’s cradle-to-cradle certified t-shirt only addresses part of the problem, since biodegradable clothing cannot be discarded of as intended by its manufacturers in municipal programs—the infrastructure isn’t there to support the recycling (Weber, 2015).

In the use and re-use phase, there are some promising shifts toward circularity, though there is still much progress to make. High efficiency laundering and eco-friendly dry cleaning are definitely moves in the right direction, but the release of microfibers and toxic chemicals are still creating waste from laundering and use. In response to that reality, Columbia recently designed its new OutDry™ Extreme jacket as the first waterproof jacket to eliminate the use of PFCs. Unlike the giant fast-fashion brands who continue to provide more and more clothing at disposable prices, other businesses are creating more and more ways for consumers to easily rent, lease, resell, repair, and upcycle garments in circularity, keeping materials in play at higher values longer, and keeping material loops smaller. The emergence of these business models means that consumer mentalities can and are changing—fashion fans seem to be buying more secondhand clothes and making their styles uniquely their own. The new business models can benefit the business too—Mud Jeans’ leasing model allows the company to retain ownership over its materials, maintaining their quality and protecting themselves against price volatility (Ellen MacArthur Foundation, n.d.). Increasing consumer awareness of circular issues and solutions across the garment value chain would help consumers know that they can create demand for sustainable fashion by changing where they shop and what they buy (Sweeny, 2015). There is too much material in the after-use phase due to consumption levels, and no feasible strategy for retrieving value from the materials. Blue Jeans Go Green calls their denim collection upcycling, but it’s actually down-cycling, since the value is being reduced. H&M’s take-back program is a nice idea, but since they haven’t found scalable recycling technology yet, it isn’t living up to its promise. Getting to the point where take-back creates value will require significant investment in process innovation, changes to how the supply chain works, and enough scale to make business sense (Bomgardner, 2016). Mud Jeans’ operating both leasing and recycling practices, though, mean that they’re operating sustainably in multiple phases of the system, which is an indicator of circularity. They’re not asking their consumers to slow down consumption though, which leads to the possibility that consumption may be less of an issue if the system is sustainable. But until the system as a whole is a lot more circular, consumption levels remain the at the crux of the issues prohibiting sustainability.

References

- Bomgardner, M. (2016, June 27). Cleaning the clothing industry. Chemical & Engineering News. Retrieved March 24, 2018 from https://cen.acs.org/articles/94/i26/Cleaning-clothing-industry.html

- BSR. (2012). Sustainable Fashion Design: Oxymoron No More? [Report]. Retrieved from https://www.bsr.org/en/our-insights/report-view/sustainable-fashion-design-oxymoron-no-more

- Bukhari, M.A., Carrasco-Gallego, R., & Ponce-Cueto, E. (2018). Developing a national programme for textiles and clothing recovery. Waste Management & Research, 1-11. Retrieved from http://journals.sagepub.com/doi/abs/10.1177/0734242X18759190

- Cataldi, C., Dickson, M., & Grover, C. (2013). Slow Fashion: Tailoring a Strategic Approach for Sustainability. Sustainability in Fashion and Textiles: Values, Design, Production and Consumption. Retrieved from http://books.google.com/books

- Council for Textile Recycling. (n.d.). The Facts About Textile Waste [Infographic]. Retrieved February 14, 2018 from http://www.weardonaterecycle.org/about/issue.html

- Cohen, N. (2014, July 11). Patagonia’s Plastic Packaging - A study on the challenges of garment delivery [Web log post]. Retrieved from https://www.patagonia.com/blog/2014/07/patagonias-plastic-packaging-a-study-on-the-challenges-of-garment-delivery

- Ellen MacArthur Foundation (2017, November 28). A new textiles economy: Redesigning fashion’s future [Report]. Retrieved from http://www.ellenmacarthurfoundation.org/publications

- Ellen MacArthur Foundation (n.d.). Mud Jeans: Pioneering a lease model for organic cotton jeans [Case Study]. Retrieved from https://www.ellenmacarthurfoundation.org/case-studies/pioneering-a-lease-model-for-organic-cotton-jeans

- FashionUnited. (2017, May 12). C&A: ‘This cradle-to-cradle T-shirt turns into compost in 11 weeks’. FashionUnited. Retrieved from https://fashionunited.uk/news/fashion/c-a-this-cradle-to-cradle-t-shirt-turns-into-compost-in-11-weeks/2017051224495

- Gardetti, M.A. & Torres, A.L. (2013). Sustainability in Fashion and Textiles: Values, Design, Production and Consumption. Retrieved from http://books.google.com/books

- Henninger, C. E., Alevizou, P.J., & Oates, C. J. (2016). What is sustainable fashion? Journal of Fashion Marketing and Management, 20(4), 400-416.

- Jung, S., Jin, B. (2014). A theoretical investigation of slow fashion: sustainable future of the apparel industry. International Journal of Consumer Studies, 38(5), 510–519.

- Kering. (2016). Beyond our limits. Sustainability Targets 2012-2016 [Report]. Retrieved from http://kering.com

- Levi’s. (n.d.). Our Forward-Thinking Methods of Responsible Production and Design. Retrieved March 24, 2018 from https://www.levi.com/US/en_US/features/sustainability

- Mantor, C. (2016, May 11). Levi Strauss & Co., Evrnu partner to launch jeans made from cotton garment waste. Fashion Network. Retrieved from http://us.fashionnetwork.com/news/Levi-Strauss-Co-Evrnu-partner-to-launch-jeans-made-from-cotton-garment-waste,691813.html#.Wqf1FJPwbOT

- Moorhouse, D. & Moorhouse, D. (2017). Sustainable Design: Circular Economy in Fashion and Textiles. The Design Journal, 20:sup1, S1948–S1959.

- Nike. (n.d.). Nike Flyknit. Retrieved March 24, 2018 from https://www.nike.com/us/en_us/c/innovation/flyknit

- Patagonia. (n.d.). 20 years of organic cotton. Retrieved March 24, 2018 from http://www.patagonia.com/20-years-of-organic-cotton.html

- Sweeny, G. (2015, August 13). It’s the Second Dirtiest Thing in the World—And You’re Wearing It. Alternet. Retrieved from https://www.alternet.org/environment/its-second-dirtiest-thing-world-and-youre-wearing-it

- Szokan, N. (2016, June 30). The fashion industry tries to take responsibility for its pollution. The Washington Post. Retrieved from https://www.washingtonpost.com/national/health-science/the-fashion-industry-tries-to-take-responsibility-for-its-pollution/2016/06/30/11706fa6-3e15-11e6-80bc-d06711fd2125_story.html

- Weber, S. (2015). How Consumers Manage Textile Waste. (Master’s Thesis, University of Waterloo). Available from UWSpace.

Stay In Touch!

Get occasional letters from Michael & Hannah.